Sustainable clothing production means that sustainable clothes manufacturers create products in a way that minimizes the environmental impacts while conserving natural resources and energy.

In making sustainable clothing, organic and eco friendly fabrics are used, working conditions at the sustainable clothing factory are ethical and fair, and the pollution emission is kept as low as possible.

More than 1500 square meters warehouse of all kinds of fabric and more than 500 square meters warehouse for accessories.

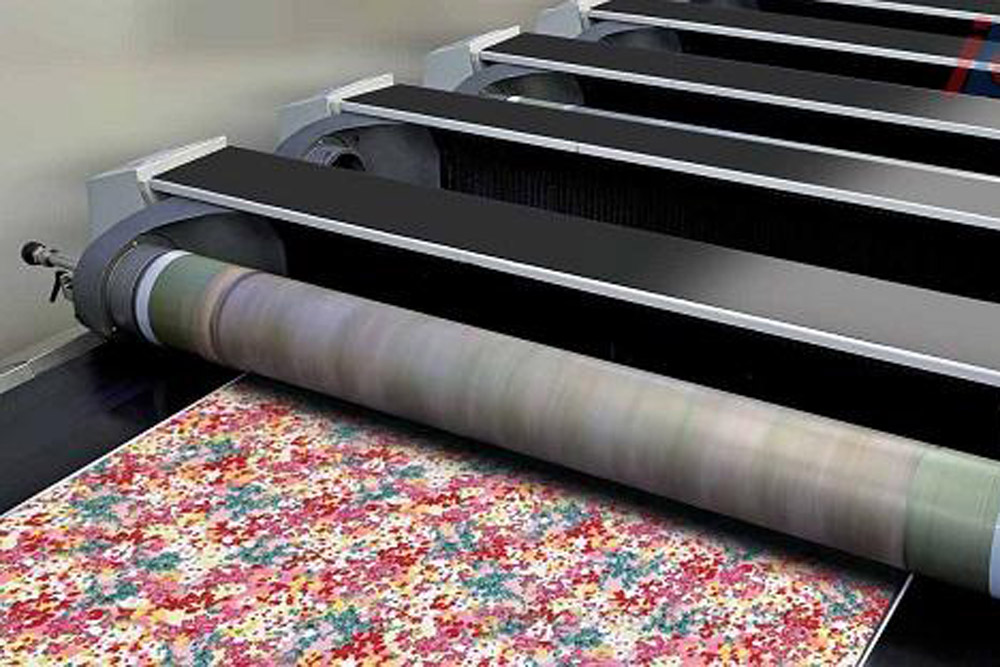

Automatic fabric spreading machine which is automatically follows the transmission device of driving cloth feeding roller, perfectly realizes tension-free fabric spreading, intelligently automatically adjust the tightness, and the edge to edge spreading accuracy is controlled. To solve the edge curling problem of knitted fabric and wrinkles happened or it's difficult to adjust the tightness of fabric when spreading the fabric by hands of workers.

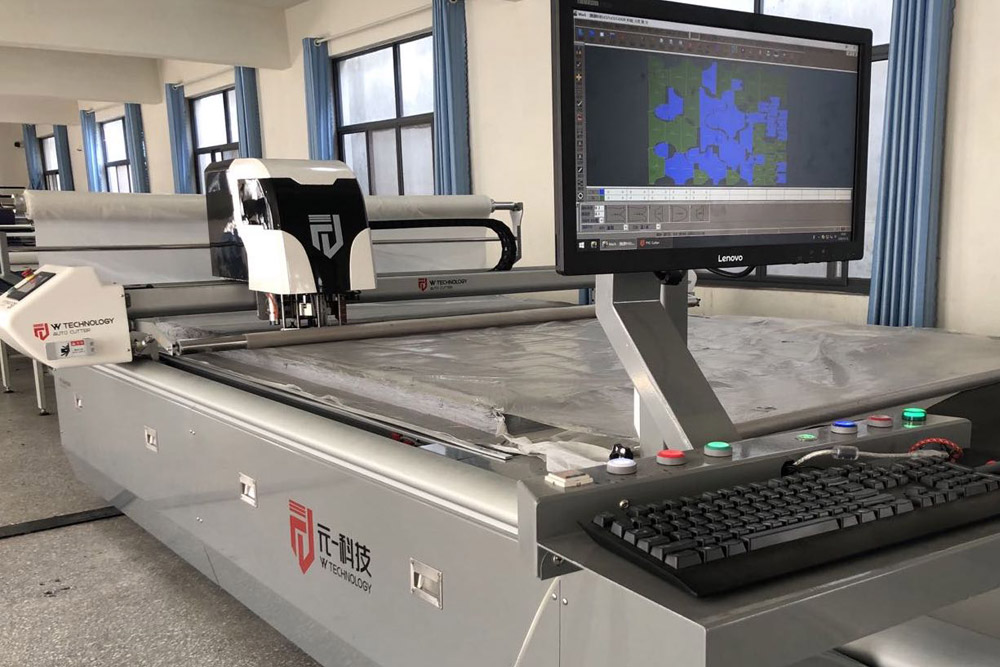

Fabric multi layers cutting machine used for proofing and cutting fabric with performances of safe, stable, efficient and accurate. It has capacity of discernment all patterns of all kinds of fabric and styles, it's independent research and development software which optimize the overcutting of blade to avoid reduce material waste and make all cut pieces accurately as patterns.

High speed automatic one-time completion of cutting, splicing, multi-needle ( bar-tacks if need) sewing and automatic feeding, to make higher quality sewing and higher productivity.

More than 300 sets all kinds of sewing machine in workshops, including multi overlock machines, single needle lockstitch machines, double needle machines, multi needle zigzag machines,3 needle flatlock needle machines, 4 needle flatlock machines, bar-tack machine, etc.

All ready-make clothing would be inspected before packaging any defects of fabric, accessories, sewing, measurements will be found and be sent back to fix or throw away if the defects can't be fixed. To make sure all things correct and good quality before packaging.

All clothing would be packed after inspection, including put the size stickers or price barcode stickers on the packaging of biodegradable plastic bag, recycled paper box or cardboard etc.

All ready-made clothing inside of inner packaging want to be inspected by this needle detector machine, to make sure no any broken needles hidden inside clothing which possible happened during sewing production.

All ready-made clothing would be packed into 5-ply or 7-ply export cartons after inner packaging finished and make sure no mistakes on information of sizes, colors and stickers. There are shipment marks on cartons which show Brand name, order number, style number, sizes and colors assortments, quantity, carton number, origin of country etc.